Wet vs Dry Polishing: Which is Best for Stone?

When it comes to polishing stone, the question of wet vs dry polishing often comes up. There is no single answer, as both methods have their uses and are better for different applications. The decision depends on the type of stone you’re working with, the grinder or polisher you’re using, and the finish you want. Let’s dive into the details so you can make the right choice for your project.

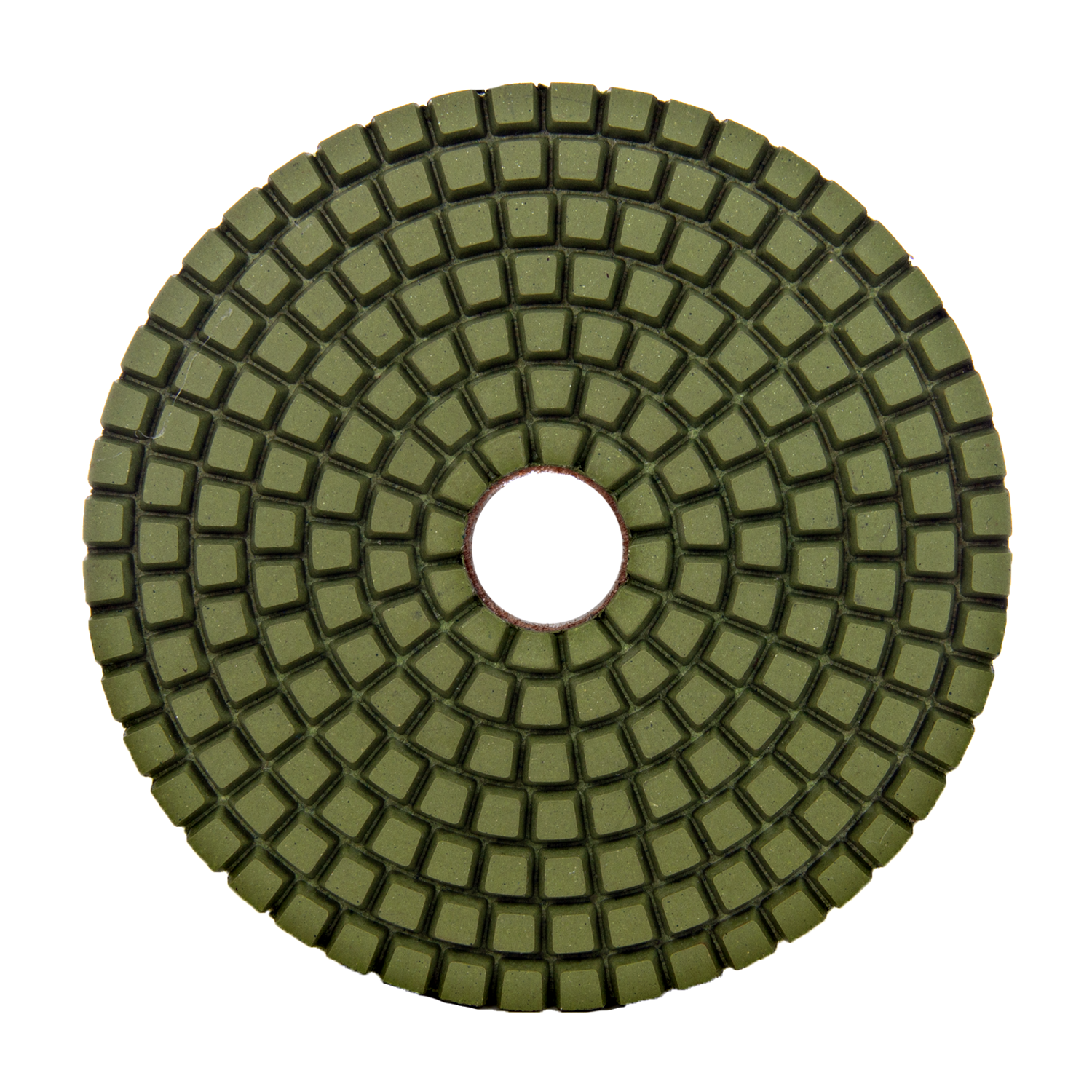

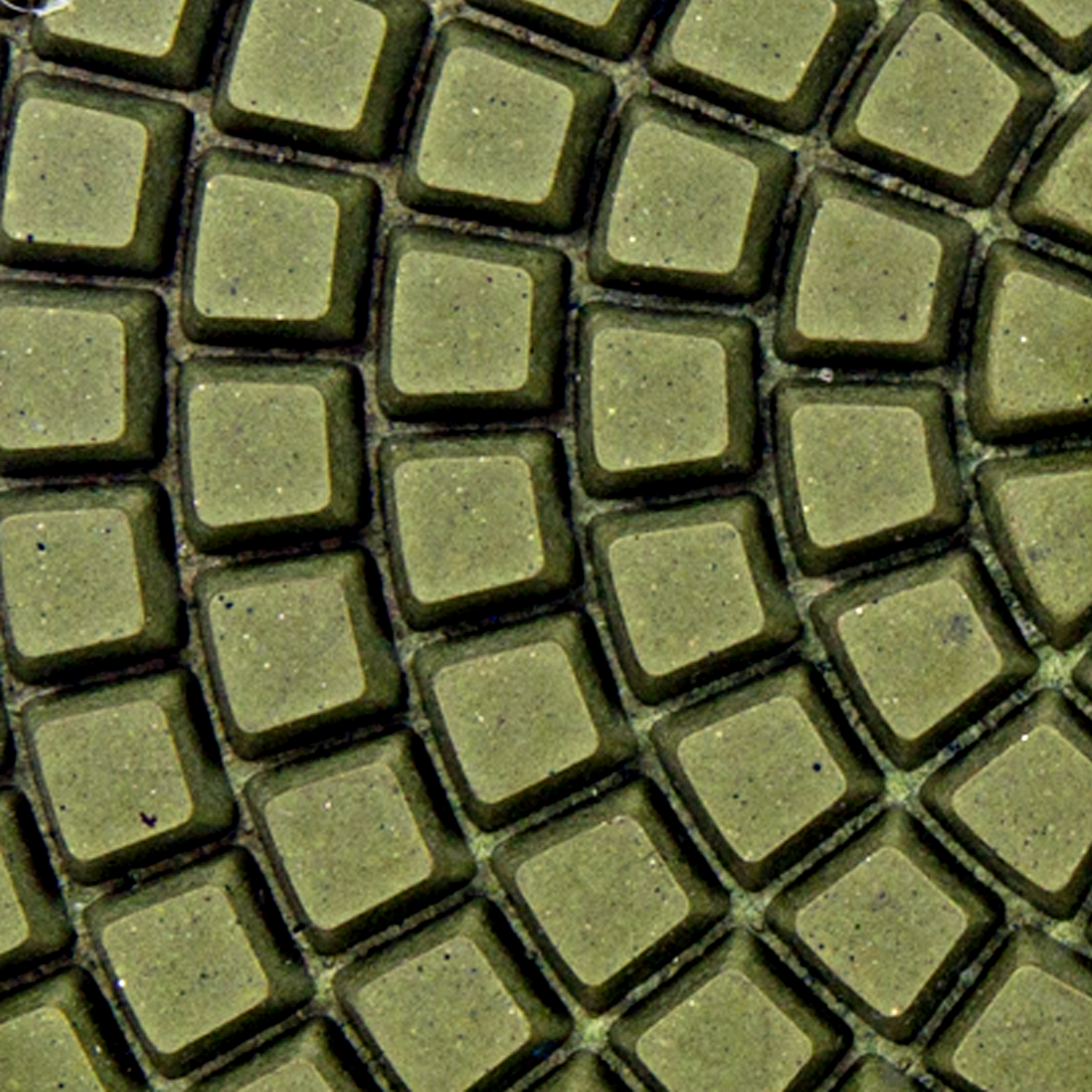

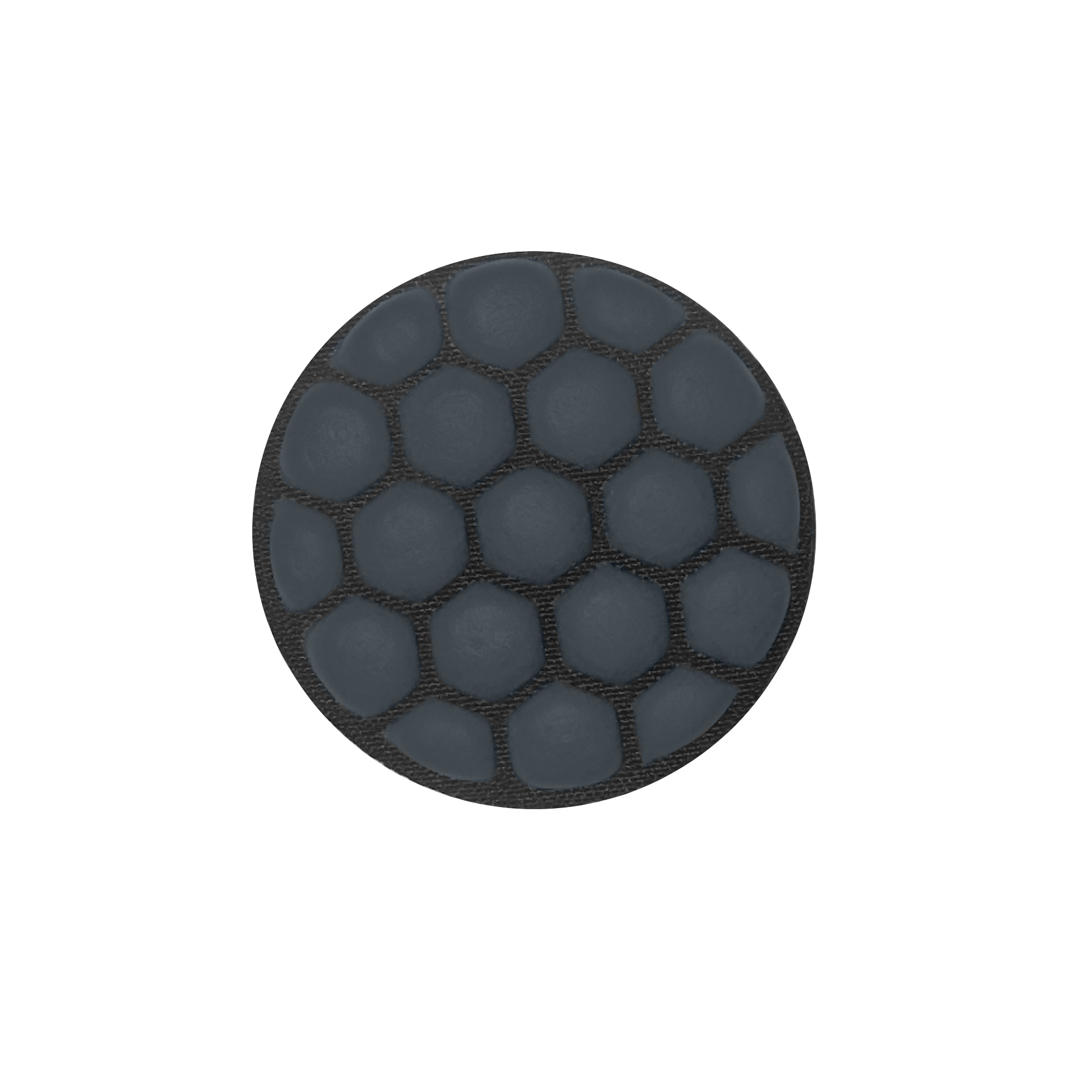

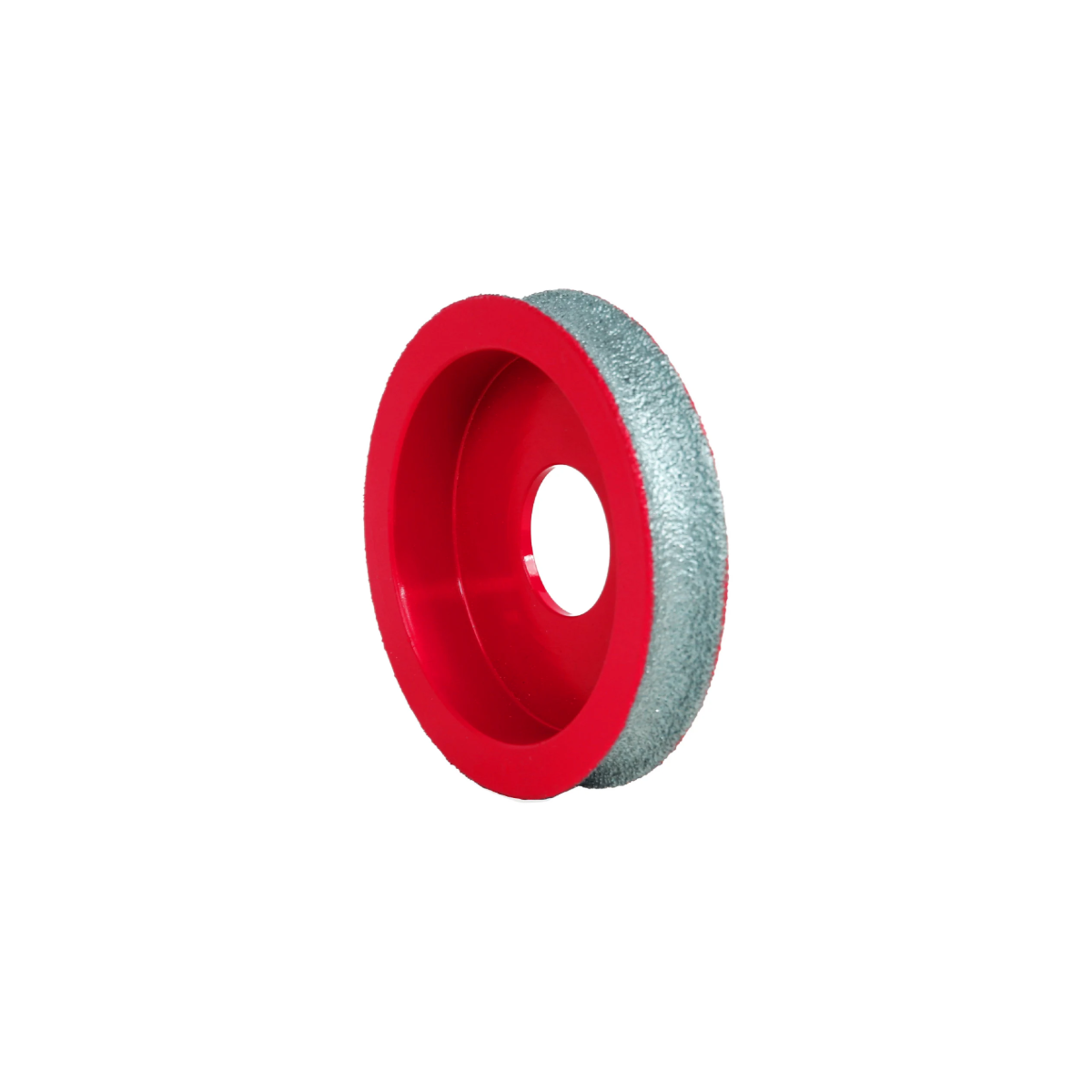

Wet Diamond Pads for Polishing Stone

Wet diamond pads are Velcro-backed pads with diamond dust suspended in resin (sometimes with copper). Water is used to cool the pads during the polishing process, preventing overheating and pad burnout.

Wet Polishing for Stone Surfaces

- High Gloss Finish: Wet polishing is often used for a high gloss finish on hard stones like granite, marble, and quartz.

- Cooler Operation: Water helps keep the pads cool, allowing them to last longer without overheating, especially on dense materials like granite.

- Versatile for Many Stones: Wet pads can polish porcelain, marble, terrazzo, limestone, travertine, and even the hardest granite.

- Cost-Effective Pads: While wet polishing requires special equipment, the pads themselves are generally cheaper than dry pads.

Wet Polishing Considerations

- Messy: Wet polishing is messy, and you’ll need protective gear like rubber aprons and wellies to stay dry.

- Specialized Equipment: Wet polishing requires machines that can handle water, which can be a higher initial cost.

Wet polishing is a standard in tile, stone, and quartz factories where a high-gloss, high-finish is required on stone surfaces.

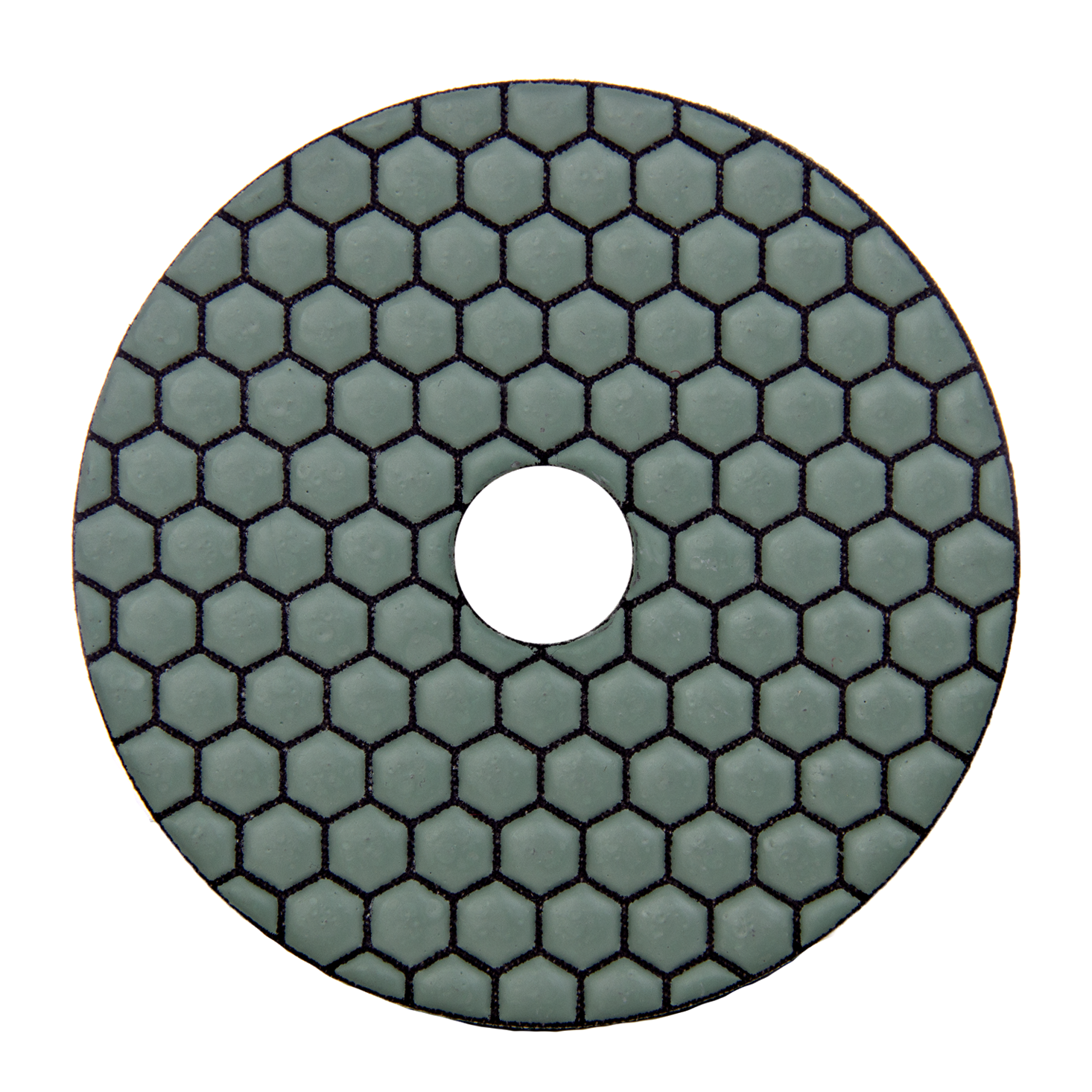

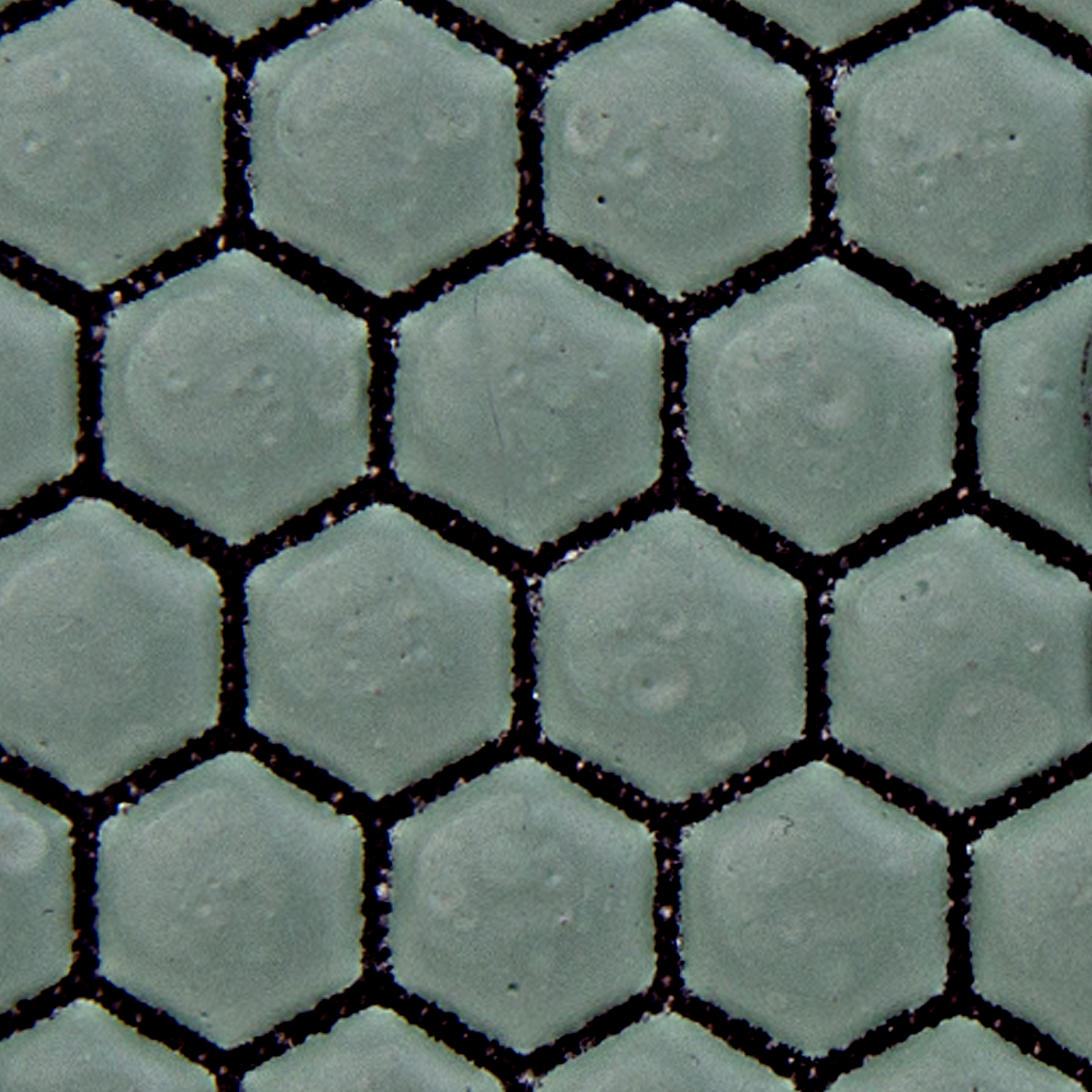

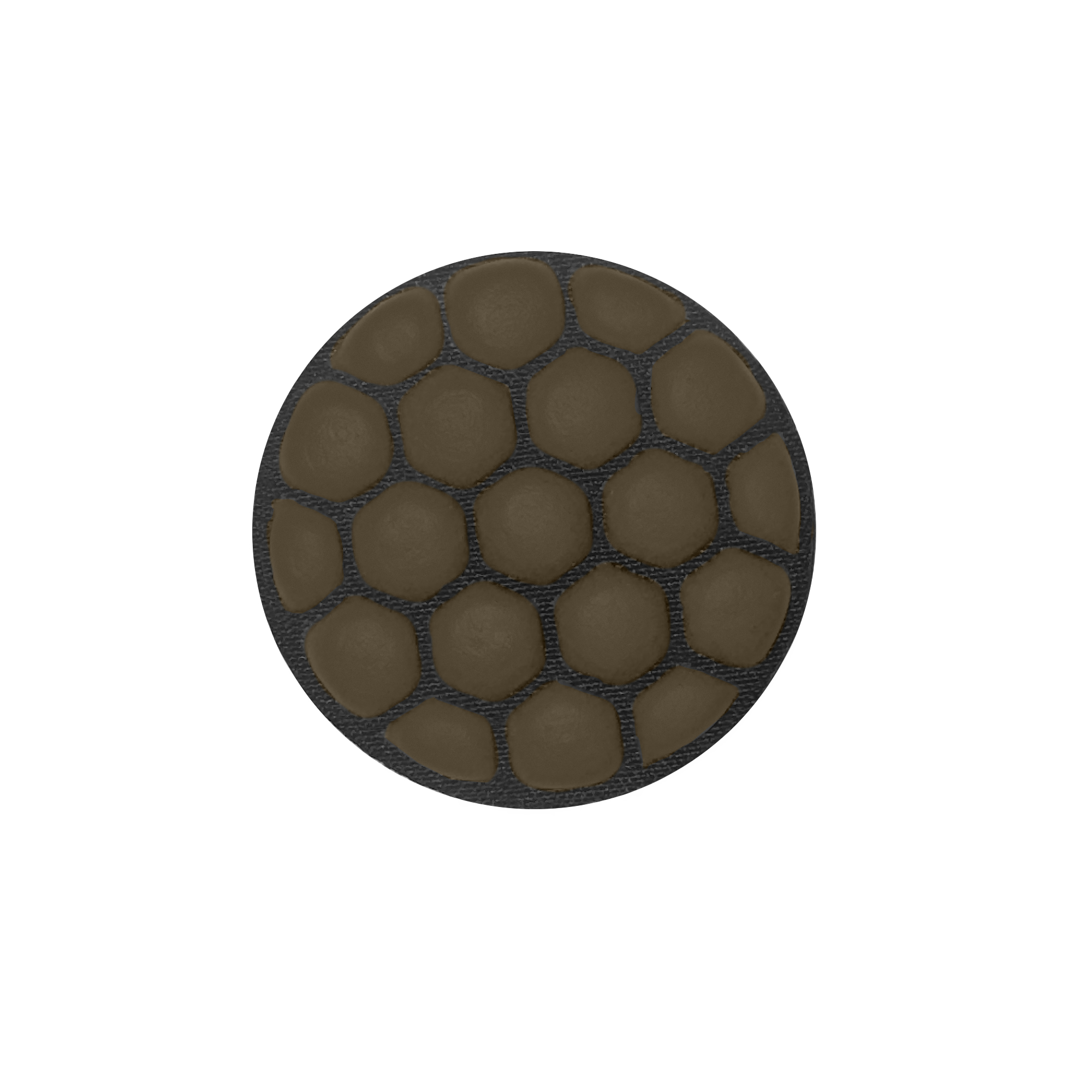

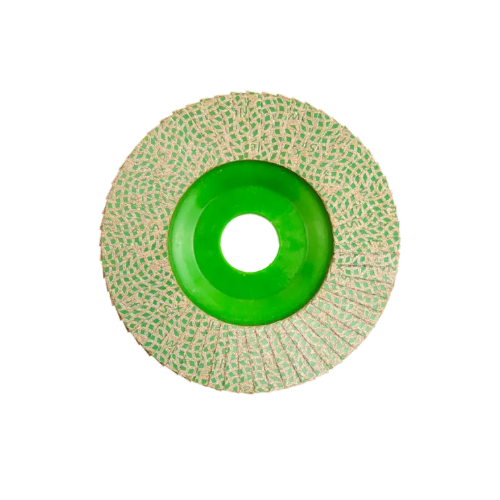

Dry Diamond Pads for Polishing Stone

Dry diamond pads contain diamond dust suspended in a denser resin, allowing them to withstand higher temperatures. These pads are used when water is not practical, such as on job sites where water is not available or when polishing finished stone surfaces.

Dry Polishing with Diamond Pads

- Convenience: No water is required, making dry polishing ideal for stone surfaces in remote areas or small jobs.

- No Water Cleanup: Since no water is used, there is no need for water drainage or cleanup, making it a cleaner option.

- Good for Hard Materials: Dry pads are excellent for polishing hard stone surfaces like granite, concrete, and other dense materials, providing a finish similar to wet pads.

Dry Polishing Considerations

- Dust: Dry polishing creates dust, especially when used on materials like quartz or engineered stone. It’s essential to have a good dust extraction system and wear protective gear like masks.

- Higher Cost: Dry pads tend to be more expensive than wet pads due to their ability to withstand higher temperatures.

Dry polishing is often used when water-based polishing is not practical, but it requires good dust management and safety precautions.

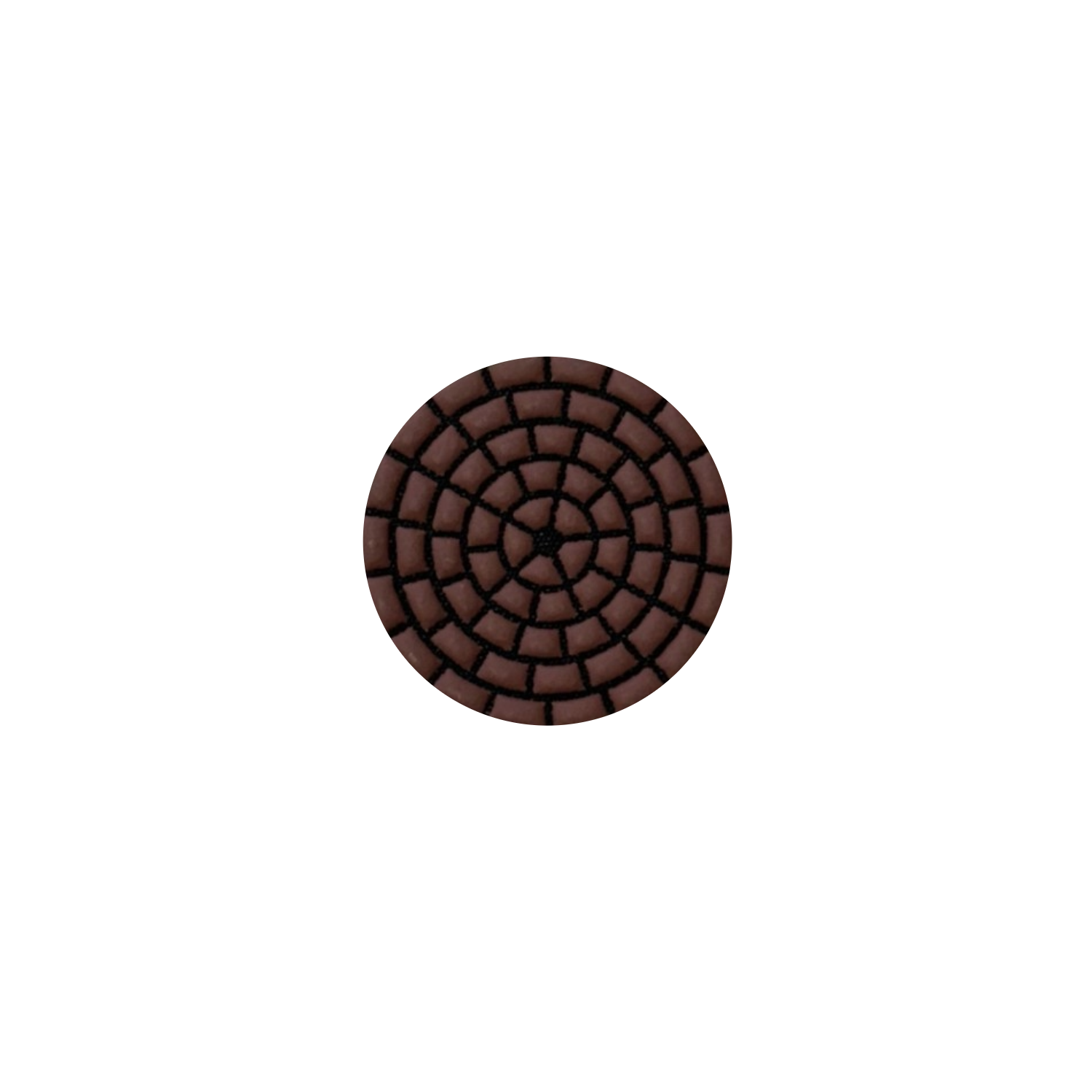

Silicon Carbide (SiC) Pads for Polishing Stone

Silicon carbide (SiC) pads are another cost-effective option for polishing stone surfaces. These pads have fine grit SiC crystals glued to paper or velour-backed discs. They are used dry and are ideal for light polishing tasks.

SiC Pads Advantages

- Cost-Effective: SiC pads are very inexpensive, usually between £0.30 to £0.45 per pad, making them perfect for small jobs or light polishing tasks.

- Versatile: SiC pads can be used on stone, porcelain, glass, and fiberglass, making them versatile for many different surfaces.

- Disposable: SiC pads are designed for disposable use and are ideal for tasks that require low-intensity polishing.

SiC Pads Considerations

- Shorter Life: While affordable, SiC pads wear out quickly and need to be replaced more often than diamond pads.

- Wet and Dry Use: SiC pads can be used dry for coarse grits (up to P-320), but for finer grits (P-400 to P-1200), they should be used wet for the best results.

SiC pads are a great option for smaller stone surfaces or when cost is a primary concern. However, for larger projects, diamond pads may be a better investment due to their durability.

Conclusion: Wet vs Dry Polishing for Stone

The choice between wet and dry polishing for stone comes down to your specific needs. Here’s a summary:

- Wet polishing: Best for high-gloss finishes, particularly on hard stones like granite, marble, and quartz. It’s versatile, cost-effective, but requires specialized equipment and can be messy.

- Dry polishing: Ideal when water is not available or for smaller jobs. While dry pads are more expensive and create dust, they are convenient and effective for hard stone surfaces.

- SiC pads: A low-cost alternative for light polishing tasks, especially when budget is a concern, but they have a shorter lifespan than diamond pads.

Make sure to consider the stone you are working with, the equipment available, and the type of finish you want to achieve when choosing between wet and dry polishing methods. For the best results, especially on larger projects, diamond pads are usually the preferred choice.