Blade Comparision

With years of cutting-edge manufacturing expertise, TORVA delivers the finest quality diamond blades available globally. Each blade is expertly crafted for precision and optimized to excel in specific tasks, ensuring outstanding performance and durability for every application.

Need Advice? Call Us

★★★★★

★★★★☆

★★★★★

★★★★★

★★★★☆

★★★★★

Wet or Dry

Wet or Dry

What are Diamond Blades?

Diamond blades are saw blades designed to cut through hard materials like concrete, asphalt, and masonry. They have diamond-coated edges for maximum durability and cutting performance. Available wet or dry, they can be used with circular saws and angle grinders. Whether you’re doing a small DIY job or a big construction job, diamond blades will get the job done.

Types of Diamond Blades

Diamond blades come in many types, each designed for specific applications and materials. Diamond blades are also known as cutting discs. Understanding the differences will help you choose the right diamond blade for your job:

- Segmented Diamond Blades: Segmented rim with diamond-coated segments separated by narrow slots. Good for cutting hard dense materials like granite, marble, and reinforced concrete. Allows for good cooling and debris removal. Heavy-duty use.

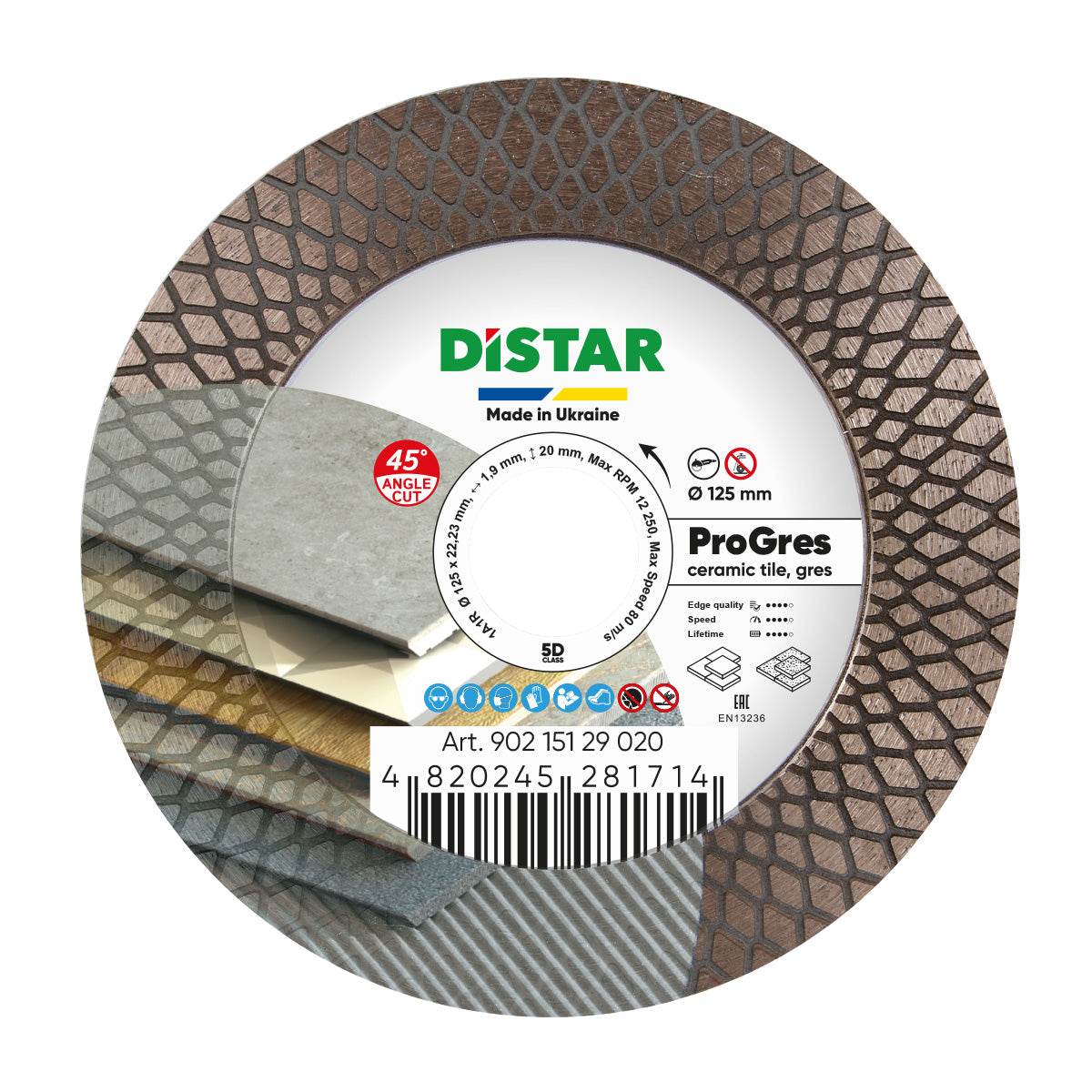

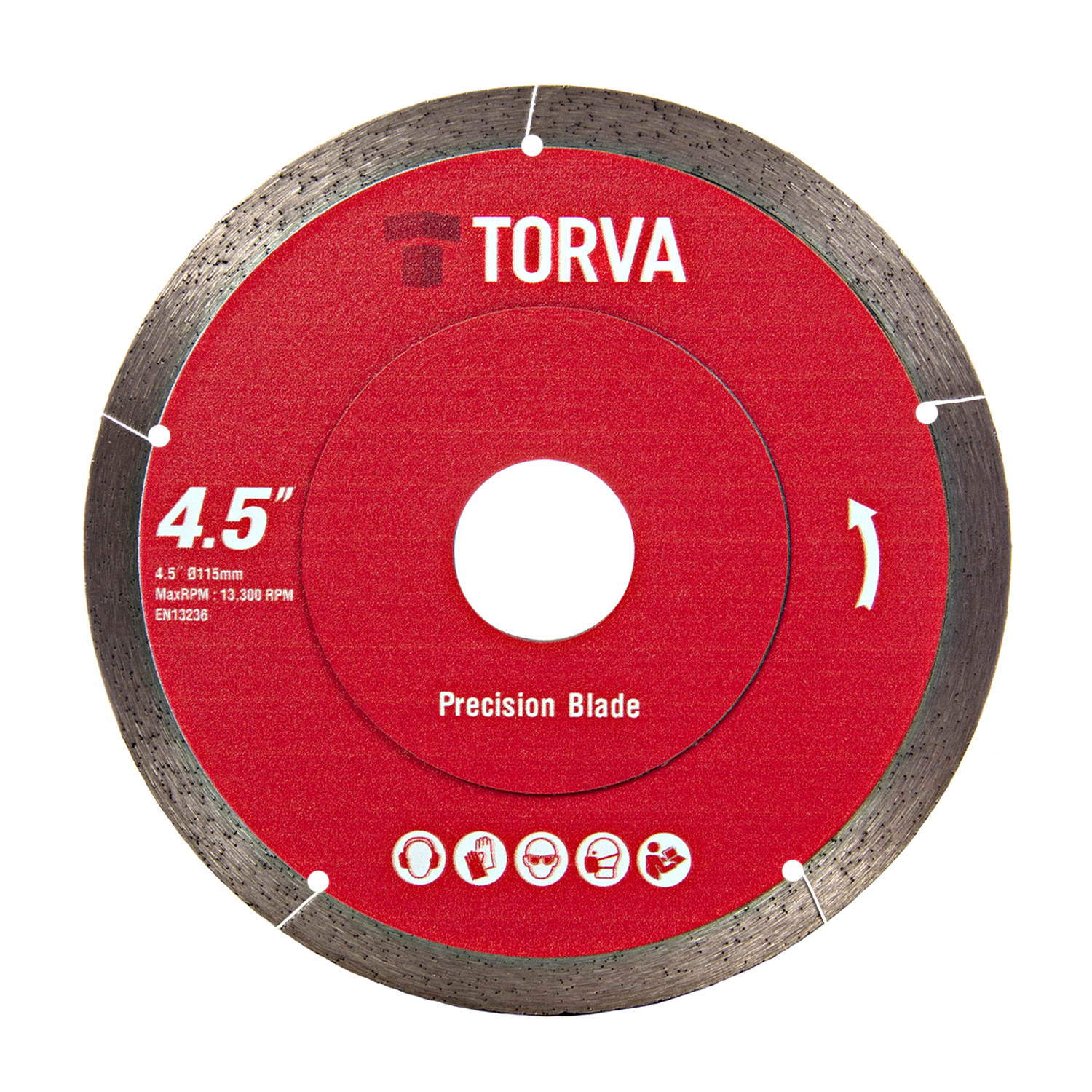

- Continuous Rim Diamond Blades: Smooth continuous rim with diamond-coated edges for chip-free cuts. Good for cutting porcelain tiles, ceramic tiles, and natural stone. Clean finish every time.

- Turbo Diamond Blades: Turbo-shaped segment design for fast and efficient material removal. Good for hard materials like porcelain, hard ceramics, and quartz. Ideal for tough jobs.

- Laser Welded Diamond Blades: Durable blades with laser-welded segment design for a strong bond between diamond segments and blade core. Good for tough materials like sandstone, granite, and reinforced concrete. Long life and reliable.

Diamond Blade Features

Diamond blades have several features that make them good for cutting hard materials. Firstly, their diamond-coated edges are very durable and cutting performance is excellent for tough materials. The diamonds are bonded to the blade with a metal matrix for strength and stability. Diamond blades come in various grit sizes (coarse, medium, and fine); each affects the cutting performance and life of the blade. With turbo, continuous rim, and segmented blades, you can choose the type that suits your cutting needs. Because of their long life, diamond blades are cost-effective for heavy-duty cutting and reliable, offering good value for money.

Choosing the Right Diamond Blade

Choosing the right diamond blade for your job can be confusing with so many options. Here are some things to consider:

- Material: Different diamond blades are designed for different materials, such as concrete, asphalt, and natural stone. Make sure you choose a blade for the material you’re cutting.

- Saw: Diamond blades are for specific saws, such as circular saws and angle grinders. Make sure the blade you choose is compatible with your saw.

- Cutting Performance: Depending on the material and saw, different diamond blades have different cutting performance. Choose a blade that meets your performance needs.

- Price: Diamond blades range from £10 to £100+ depending on type and quality. Consider your budget and the job requirements when choosing.

By considering these factors, you can choose the right diamond blade for the best performance.

Diamond Blade Uses

Diamond blades are very versatile and essential tools for many applications:

- Tile Cutting: Porcelain tiles, ceramic tiles, and natural stone tiles. Diamond blades give you precise cuts for a professional finish.

- Roof Tile Cutting: Concrete and clay roof tiles. Diamond blades make roof tile cutting easy and clean.

- Building Material Cutting: Reinforced concrete, brick, and block. Diamond blades are ideal for construction jobs.

- Natural Stone Cutting: Granite, marble, and sandstone. Diamond blades provide smooth and precise cuts and preserve the material.

- Abrasive Material Cutting: Diamond blades can also cut other abrasive materials like drywall, plaster, and fiberglass. They are versatile and efficient for many jobs.

Safety and Maintenance

Safety and maintenance are key to ensuring the best performance and longest life for the diamond blade. Here are some tips:

- Wear Protective Gear: Always wear safety glasses, gloves, and a dust mask to protect yourself from debris and dust while cutting.

- Use Proper Cutting Technique: Maintain a steady feed rate and gentle pressure to avoid damaging the blade or the material. Proper technique will give you a clean cut and a longer blade life.

- Clean the Blade: Clean the blade regularly to remove debris and prevent buildup, which can affect performance and damage the blade.

- Store the Blade: Store your diamond blades in a dry and secure place to prevent rust and damage. This ensures they’re ready to use when you need them.

- Inspect the Blade: Check the blade for wear and damage before each use. Replace the blade if necessary for safety and optimal cutting performance.